WHEAT:NEWS JANUARY 2019 Volume 10, Number 1

Sneak Peek: WTOP Installation

Here is a quick preview of the massive News Room RadioDNA is building for WTOP. Facility launch is early February. Stay tuned for more updates! Thanks Rob Goldberg from RadioDNA for the video!

Mike Erickson To Talk Processing at Raleigh SBE Meeting, Jan 29

Save the date!

The Raleigh SBE Chapter's monthly next meeting is on January 29th at 11:30am at the Golden Corral at 6129 Glenwood Avenue in Raleigh. Their guest speaker will be Wheatstone's own Mike Erickson. Mike is our system and support engineer for Wheatstone Audio Processors. He helps customers all over the world shape their sound, from processing for AM and FM stations to processing for microphones and audio streams. Below is the agenda...

Audio Processing 2019. New Ways to Enhance the Listening Experience.

We all know audio processing does three things: it keeps you compliant, it improves the listening experience by adjusting the audio levels and it creates a sonic signature for the radio station. As technology has evolved, so has the audio processor, and a new set of goals have been established. Mike Erickson will let you know what you should be looking when deciding on your next processor.

If you want to know where you’re going,

you have to first know where you’ve been

Below, we take a quick look back on the stories and the people that defined the year and point to what’s ahead for our industry in 2019.

Radio News:

Chicago's WDRV The Drive Goes Live

MAY 2018: Our crew was there when Hubbard Radio cut over to its new studios at One Prudential, Chicago. We had to see for ourselves the studio that now houses a 37-module frame LXE console, the largest LXE console delivered to date. We walked away from this major install with the realization that although studios and technology are getting smaller, radio is still very much a big production!

WDRV (97.1, The Drive) is now rockin’ from Hubbard’s new studios at One Prudential, Chicago. On May 11, Bob Stroud and the midday team boarded a double-decker bus and headed down Michigan Avenue from the John Hancock building, which had been WDRV-FM’s home for 17 years, to the new studios at One Prudential.

WDRV-FM is the first of Hubbard’s three Chicago stations that are making the move to One Prudential.

Two more on-air studios, one more production studio, and two more producer studios will be completed over the next two months for WSHE-FM and WTMX-FM. This first completed studio houses the largest Wheatstone LXE console delivered to date -- a 37-channel strip frame that’s been programmed with ConsoleBuilder according to the custom features specified by WDRV-FM CE Kent Lewin along with integrator RadioDNA President Rob Goldberg. It features four LX-SS strips which, like the LXE, can be programmed to handle the execution of complex tasks.

Our Bob Martin was there with the cameras and put together this short video of the cutover. (Spoiler: the first song played from the new studio was the Stones' “Start Me Up,” of course).

Surviving Smaller Market Studio Projects

JUNE 2018: We’re well-known for our impressive major-market studio projects. But during the year, we also quietly worked on a few impressive small-market studio projects. In this article, RadioDNA’s Rob Goldberg and Gabriel Media’s Deb Huschle walk us through a studio project in St. Cloud, Minnesota, that was as complex in its own right as any studio project in Chicago or Boston.

Putting together a new studio facility can be a challenge for any broadcaster, in the same way that contenders on the "Ultimate Spartan Challenge" are challenged by moving obstacles, snake pits and impossible deadlines.

But for smaller market broadcasters? Think "Survivor."

“The biggest challenge is budget, of course. But it might surprise people to know that the smaller market projects are often more complex and for that reason, can be more cutting edge than what you’d find in Chicago or Los Angeles,” said Rob Goldberg, who has managed projects on both ends of the spectrum as the CEO of RadioDNA in Minneapolis.

He said stations living on the margins are more reliant on automation, both for programming as well as for general operation. “They’re tossing around different satellite feeds and they’re often much more intense on remote broadcasts. And, coming more into fruition is doing remote broadcasts without having board operators. They want to save the budget of having to hire a live body just standing around and pushing buttons,” he added.

All of that requires more logic, more integrated routing and more engineering – even as engineers are in short supply at most smaller market stations. Many can’t afford a full-time engineer and instead share a contract engineer with other stations in a region, which doesn’t bode well for the day-to-day grind of studio building. That leaves management running the show, and out on Ghost Island without a paddle.

Deb Huschle, the GM of Gabriel Media in St. Cloud, Minn., has been there and back. Gabriel Media is a nonprofit that originated program for AM talk station K-YES 1180, Christian music FM Spirit 92.9 and an LPFM from its studios in Sauk Rapids, until parking became an issue. The Christian broadcaster purchased commercial property in downtown St. Cloud and set out more than a year ago to build a two-station studio that involved a total renovation down to the studs, and all new gear, save for an AudioVault system that they moved over from the old facility. They went with IP-12 control surfaces, TS-4 talent stations and a facility-wide WheatNet-IP audio network that Goldberg and his field engineers at RadioDNA configured and project managed. The new studios went live in January; no major obstacles, no missed deadlines, and no more worries. It’s all one big automation backbone from one end of the facility to the other.

Huschle’s advice to smaller market broadcasters about to install new studios: “Count on equipment to do more,” she said. “Being able to control things through WheatNet-IP from your phone or your laptop or whatever while you’re in the field, it’s really a cost benefit for these smaller markets,” agreed Goldberg.

For most projects, Gabriel Media’s included, RadioDNA field engineers tightly integrate the program automation system into the WheatNet-IP audio network using the Wheatstone ACI protocol. This gives them the framework to control automation functions from anywhere on the network, or from outside the network through an Internet connection. Through the ACI, they’re also able to connect codecs directly into the WheatNet-IP system. When Gabriel Media talent use a codec for a remote in the field, all control can be done with their phone or laptop, to bypass the studio and subsequent need for a board op, for example.

That communication goes the other way, too. “We’re able to troubleshoot through WheatNet-IP. Once we set up a system, we can or Mark (Young, Gabriel Media’s contract engineer who is also the fulltime engineer for Townsquare Media nearby) can just dial in and troubleshoot or make that crosspoint change or add that logic function,” said Goldberg. As we write this, Gabriel Media is preparing for a new FM translator for AM K-YES 1180, which will no doubt burn up the lines between RadioDNA and station staff to make the required changes.

For all his installs, Goldberg color codes and maps out signal paths so that changes can be made by staff on-site with minimal instruction from a remote engineer if need be. “Just having that and being able to tell someone like me with no technical training what wire to change or what to do in an emergency, that is peace of mind,” commented Huschle.

Limit the Multipath

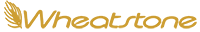

FEBRUARY 2018: An accidental L-R attenuation experiment and an NAB meet-up by two guys who used to engineer the same station resulted in a multipath solution for a Denver station. Some of our best moments in 2018 were spent in the field, applying what we learned in the lab to real issues facing broadcasters. This article is in remembrance of Wilks Broadcast Group DOE Barry Thomas, who left us far too soon.

It happens. Especially to 92.5 The Wolf, which broadcasts a rimshot signal into Denver from the base of the Rocky Mountains with enough effective radiated power to make up for an antenna barely clearing the average terrain.

The geography, the antenna height, the Class C1 power – together they form the perfect storm for multipath. And sure enough, anyone tuning into 92.5 while commuting between Denver and the bedroom community of Castle Rock could discern the nasty effects of multipath. Until three years ago, the Country station was virtually unlistenable over half its contour area as car radios tried to lock onto multiple versions of the same radio signal bouncing off the mountains.

Barry Thomas, the Director of Engineering for Wilks Broadcast Group, which owned The Wolf, had tried everything. He tried indiscriminately reducing the stereo separation and cutting way back on the composite clipping, a known antagonist to multipath effects like picket fencing and flanging.

Both required compromises, especially in loudness. But Wilks’ programming VP as well as its CEO Jeff Wilks were determined to hang on to loudness and any other competitive advantages they had for the remaining half of the Denver market that could actually tune into the station.

Then, a little over three years ago, Thomas attended an NAB session presented by our Jeff Keith, who had accidentally discovered the effects of program-dependent L-R attenuation on perceived multipath when he designed a mono loudness controller device using the technique for an oldies station he engineered back in the ‘90s. Thomas knew well the station that Keith had mentioned in his presentation; he was the chief engineer of that same station before Jeff!

He began to think Jeff was onto something: What if they could reduce the L-R stereo information just enough for the radio to hide the blend to mono by modifying the energy in the 38kHZ stereo subcarrier? “I knew that reducing the L-R would help, because less energy around 38kHz means that the radio isn’t reacting to trash in the stereo section. And depending how the radio figures out when to blend and when not to blend -- some look for noise around 19kHz and some look for the overall noise floor around 38kHz – the results could be significant,” said Thomas.

He quickly learned that Keith had tested the technique on dozens of radios (the findings are presented in his paper New Findings on FM Stereo Multipath Control) and once sufficiently satisfied, had added the Multipath Limiter to the Wheatstone FM processor line as one more tool for dealing with multipath. “What our Multipath Limiter does is reduce the magnitude of volume fluctuations due to multipath-induced blending by managing a program content's L+R/L-R ratio under very specifically controlled conditions. By intelligently allowing only enough stereo information to fool the ear into believing it's a full stereo signal, the audibility of blending is reduced. The psychoacoustic result, then, is that multipath has been reduced and perceived coverage improved,” explained Keith, Wheatstone’s senior product development engineer.

Thomas convinced his CEO to give it a try, ordered Wheatstone’s flagship processor, the AirAura X3, and put it on the air. He drove to the multipath hot spots and listened to the results from a sampling of radios. “Damned if it didn’t do what Jeff said it would,” said Thomas, who called the station CEO and CFO to report the results. “They immediately called BS on it, saying that no processor could do that! So they hired Pete Salant to come to town for a third-party evaluation. I appreciated that because it was a really great, exhaustive experience that confirmed what we were all hearing.”

Salant, a programmer who took NBC Radio’s New York City FM flagship station WYNY from number 22 to number one in adults 25-54, arrived in Denver a few weeks later with his test gear: a pair of golden ears. The programmer, who has since changed careers, has played classical piano since the age of three. As a 12-year-old, he could identify stations with his eyes closed just by their sound.

Our field engineer Mike Erickson, who Salant commented “possesses the other pair of golden ears,” also arrived in the Mile High City. Listening comparisons began immediately. “It was Pete, Mike and me living in and out of vehicles for three days,” said Thomas.

“We started driving around and doing A-B comparisons. And as soon as we turned on the X3, the signal went from an unlistenable mess to one that sounded entirely competitive. I couldn’t tell you what was going on in that X3, but it was definitely mitigating 90 percent of the multipath,” said Salant, who admits to being stunned by the results. “I mean, half of the metro just couldn’t listen to that station because of the signal. Even if you were trying to listen at a static position, if you moved even two or three inches there was that flanging and multipath distortion. It was all gone with X3,” he said.

Even more incredible, because stereo attenuation is program dependent rather than set at, say, 3dB or 6dB across the board, the Multipath Limiter got the job done without driving away listeners. “It wasn’t obvious to me that there was less L-R, which was a relief because taking away the stereo takes away from the listener experience. The more the sound can come from the doors of the car, the louder it seems and the more it wraps around you and hypnotizes you into listening longer,” commented Salant. In fact, 92.5 The Wolf has seen a steady climb in TSL since installing the AirAura X3 three years ago.

What’s more, the station was able to eliminate composite clipping entirely. “The look-ahead limiter in the X3 effectively gave us that loudness so we lost the composite clipping and all the trash that comes with a clipper, which had contributed to some of the problems we were having in those multipath areas,” explained Thomas.

“I don’t know what they put in that box, but there’s just no overshoot,” added Salant.

Not only did the X3 never leave The Wolf, Wilks purchased two more X3s for Denver stations Mix 100 and KOOL 105.

For details on L-R attenuation and multipath, download Keith’s paper New Findings on FM Stereo Multipath Control.

Color Me Red

AUGUST 2018: The PR&E legend continues and the love for this brand was more evident than ever during 2018. Here is a very colorful story about one BMX board that was found during a salvage run and lovingly restored by a PR&E fan after serving part of its life in a bomb shelter.

This very colorful console (pictured right in its restored state) is the legendary BMX originating from KILT in Houston. Number-one PR&E fan Scottie Rice, who started the Pacific Recorders & Engineering Fan Club page on Facebook, is in the process of restoring this 1979 board. It doesn’t have a serial number and is believed to be PR&E’s first custom-made console, laminate inserts and all. Rice ended up with this gem as part of a four-board salvage run to KFWB’s transmitter site in East Los Angeles a few years back.

It was crated at the time, so he had no idea the bad shape it was in – he said it was one of the filthiest BMX boards he’d ever seen. (Which is saying a lot, because Scottie has quite a collection of BMX boards). Later, when discussing the board with PR&E founder Jack Williams, he learned that the chief engineer at KILT had ordered the board with colored modules. As the story goes, after KILT retired the board in the 1990s, it was sent on to Group W station KFWB in Los Angeles for use in the bomb shelter studio at the transmitter there, which is where Rice rescued it.

In a weird twist of irony, the board was built in San Diego, shipped to Houston, then to Los Angeles, and is now back in San Diego where it is being restored by Scottie at his home there. In fact, the laminate covers were made by an engraving shop in San Diego not too far from where Scottie Rice lives. In these before and after pictures, you’ll see how much restoration has gone into this piece of history. Scottie has refinished the wood, stripped the frame and washed it, and cleaned all the modules. It’s almost completely restored, and it still runs!

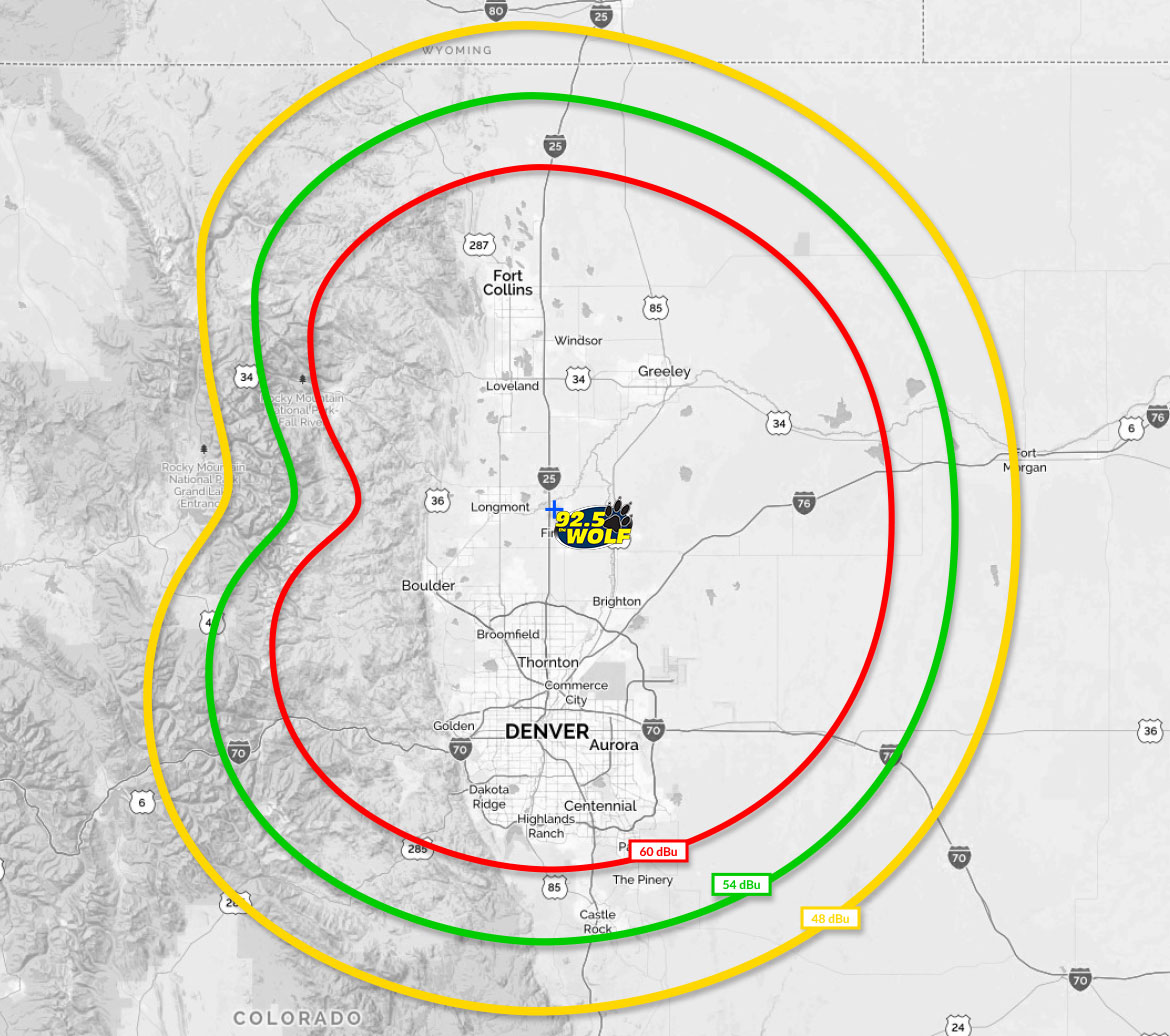

Panthers in the Factory

MARCH 2018: When we found out we were customizing LXE consoles for our home-state football team, the Carolina Panthers, we had to follow along with our cameras. If you’re a sports fan, you’ll understand. There is just something magical about sports and radio.

Our cameras followed along as new studio gear for the Carolina Panthers wound its way through our factory. Collegiate sports broadcaster IMG ordered two customized LXE consoles, some TS-4 talent stations and a few M4IP-USB mic BLADEs for a new Panthers studio that will be integrated into its large WheatNet-IP networked studio complex in Winston-Salem.

We started in the metal shop, where we found Rodney running the CNC punch press to turn out the module faceplates for the LXE. Check out the precision of this machine!

As the system for the Carolina Panthers continues to make its way through our factory, piece by piece, Sylvia Artis, our test department boss, performs quality control inspection on each of the modules destined for the Panthers' LXE consoles. This thorough visual and mechanical quality control inspection ensures that every part is perfect prior to assembly.

In the metal shop, our computer-controlled laser cutter is swiftly slicing out metal plates for the Carolina Panthers’ special, custom-designed panels. The laser boasts 1,000 watts of power, and is gas-assisted. It's quite fun to watch it in action!

Photo above: Hubbard Phoenix, design and installation by RadioDNA

JANUARY 2018: We started 2018 by telling you about four studio trends that were making sweeping changes in studio buildouts. Those trends – visual feedback, video in the studio, virtualization of functions and simplistic design – are still going strong. We will be keeping an eye on these trends, and others as they develop, to bring prosperity and productivity to our broadcast customers throughout the New Year.

Photo: Right, Rob Goldberg, Owner RadioDNA.

Studio projects can go wrong in spectacular ways. More often though, broadcasters tell us that the biggest issue they face is a persistent, nagging feeling that something is missing.

Sometimes, it’s their keys or phone that have gone missing yet again in the chaos of a new studio buildout. But often, what’s missing are a few critical studio additions that were not even on the table five years ago.

RadioDNA’s Rob Goldberg walks us through four studio trends that every broadcaster building or adding onto a studio should be thinking about today. Goldberg and his company of engineers have designed, installed and managed studio projects for Entercom, Gabriel Media, Hubbard, Ingstad Media Family, Jackson Rancheria Radio, Leighton Broadcasting, Minnesota Wild Network and Results Broadcasting.

Light up the studio. Any modern studio today is likely to have IP audio networking and that means talent no longer monitor off-air. What they’re hearing in their headphones is a local mix, so visual feedback becomes more important than ever, according to Goldberg. For visual monitoring and other purposes, he sets up the GPIO in our WheatNet-IP audio network BLADEs to control Yellowtec’s Litt LED signaling trees. When the tree is lit red, it means the studio is hot and on the air. When the light is off, the console is in voice track mode. Green status and a slow blink might indicate that there are 30 seconds left of a song and to prepare for live broadcast.

LED status indicators let talent know there’s a caller on the line, whether an EAS alert is about to happen, and if any station in the group is off-air for any reason. In the case of the Minnesota Wild sports studio, Goldberg set up LED indicators so that if remote talent dialed in on the ISDN line from the field, the producer would know immediately in the studio. Any standard automation system can talk to the WheatNet-IP audio network BLADEs, which control LED trees and indicators as an integrated system. Doors, clocks, even the coffee maker can be monitored with status indicators. “When the coffee’s ready, just have it light up a light,” says Goldberg.

Make it visual. With 5G unlimited wireless data just over the horizon, video content is about to happen in a big way. Goldberg suggests stations get in now by installing video cameras in the studio and slaving those cameras to microphones for their social media feeds, for example. “The easiest way to integrate that into the studio is through WheatNet-IP because you can literally ‘ACI control’ the cameras,” says Goldberg, referring to Wheatstone’s Automation Control Interface that is used to integrate standard camera automation applications into the network.

With this, you can automatically control camera switching based on whether a mic is on, the mic fader is up, and audio from the mic is coming across as meter data. Cameras can be slaved to mics based on all or just one or two of the criteria, and they can be panned to capture live video of a panel of guests when two or more mics are opened up.

Automating camera operation through the IP audio network relieves producers of yet one more thing they have to deal with during a busy show, and can be beneficial for editing packages after the show. “It all looks professionally done, but it’s automated,” explains Goldberg.

In much the same way, graphics or sponsorship logos can be made to appear on the station website or Facebook feed during, say, a call-in show or a spot.

Virtualize it. Goldberg is laying out virtual mixers set in touchscreens using our WheatNet-IP ScreenBuilder app and setting these up as producer positions in newsrooms. “In some cases, we don’t install mixers in the newsroom at all. We are in the process of setting up a bank of virtual mixers with 35 news positions at a Hubbard facility,” explains Goldberg. The benefits: reduced hardware expense and maintenance, an easier way to make changes as needed, and the ability to add mixing and other talent controls in smaller spaces.

Keep it simple. Today’s modern studio is all about simplifying things too. What’s missing in most of the studios Goldberg designs these days are clunky box speakers in favor of speakers recessed into the ceiling, automation PCs in deference to virtualized server systems in the TOC, and extra cables for internet connectivity thanks to WiFi connectivity.

Overall, at the end of the project, you should end up with less that does more.

WBZ Boston Shuffle

OCTOBER 2018: CBS’s spin-off of its radio division the previous year set in motion a complicated ownership shuffle in Boston. Scott Fybush drove to Boston after the dust settled.

In this article, he untangles the mystery of who ended up where and with whom, and tells us how it all shook out for the iconic brands, sports teams, and stations in flux. The Great Boston Shuffle taught us all about the incredible mobility of station operations today.

By Scott Fybush

CBS spun off its radio station division last year, which set in motion a complicated Boston chess game in which WBZ 1030 ended up in the hands of iHeartMedia and WBZ 98.5 ended up as part of the Beasley cluster by way of the Entercom-CBS Radio merger.

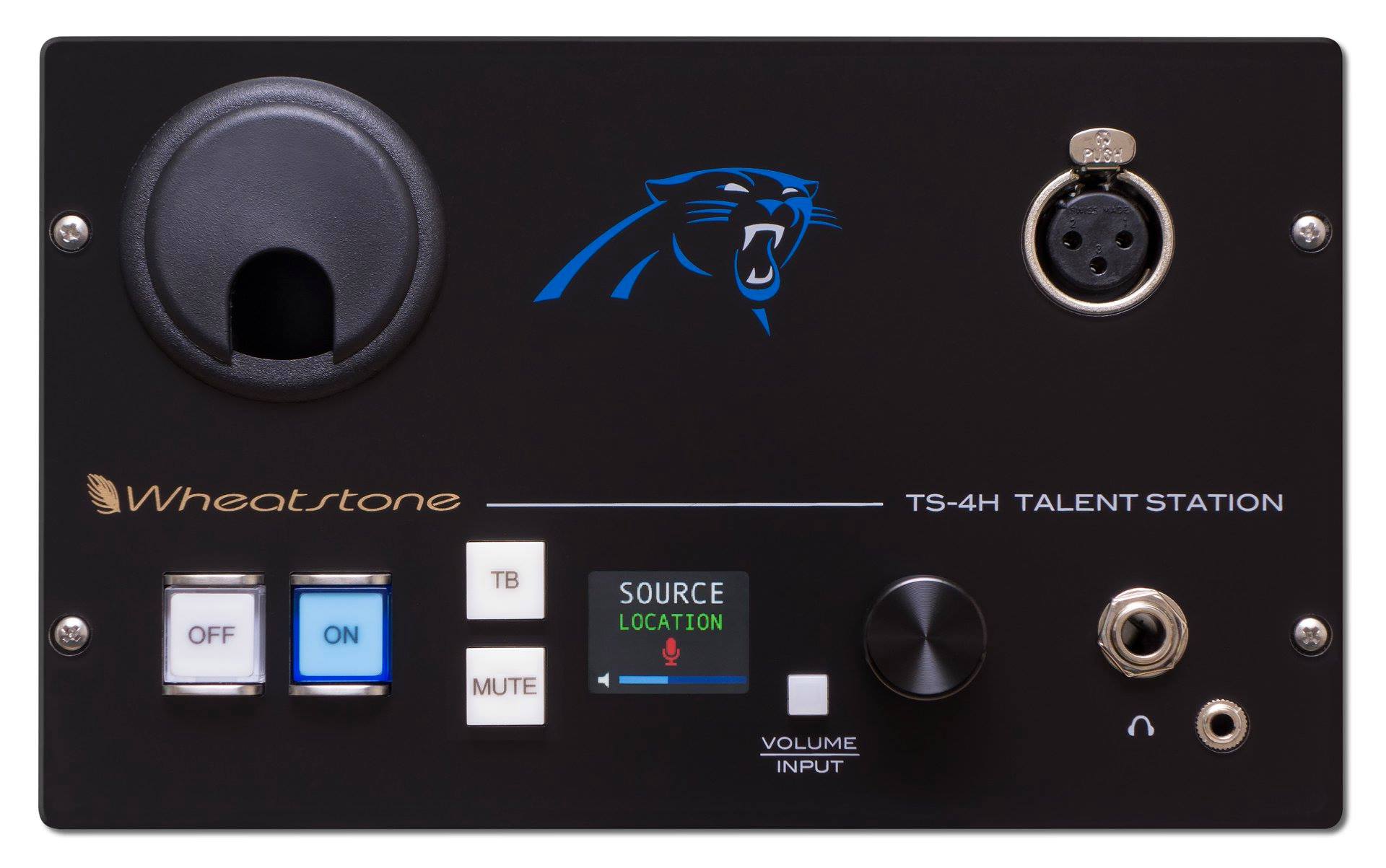

WBZ 1030 moved into iHeart’s newly expanded studios in Medford. Meanwhile, over at the Beasley studios in Dorchester, MA., CE Dennis Knudsen and his colleagues carved out two former production studios to create a big, beautiful new space for 98.5 The Sports Hub. Although both WBZs are now separated by geography and ownership, they share something in common: both are using LXE consoles and WheatNet-IP audio networking.

During my swing through Boston to visit my alma mater, WBZ 1030 (you can read about it in last month’s Wheat News or Radio Insight Tech), I decided to stop into the Sports Hub’s new studios to see how it all came together.

I found The Sports Hub studios situated at the front of Beasley’s second-floor studio core on Morrissey Boulevard, just south of downtown Boston along the harbor near the JFK Library. Beasley runs five FM stations here, but this one consumes a disproportionate share of resources because of all the programming it produces. The Sports Hub originates the networks for three of Boston's big four sports teams: the Patriots, Bruins and Celtics. (And don't forget about the major-league soccer team, the New England Revolution!) Adding in live local sports talk all day long and TV simulcasts of the midday and afternoon shows on NBC Sports Boston, and it’s no wonder they built two control rooms instead of just one.

Sports Hub morning co-host Fred Toucher takes control of his studio mics with the LXE console in his air studio.

An LXE console in the Sports Hub air studio provides an extra layer of control for air talent, including morning co-host Fred Toucher.

Wheatstone technology helps provide maximum flexibility for the Sports Hub's busy format. The air studio feeds not only radio but also several simulcasts on NBC Sports Boston, which controls the studio lighting and video screens.

Wheatstone's LX-24 console is the nerve center for the Sports Hub's main control room, with a view into the busy air studio.

To the right of the main console in each control room, a Wheatstone L-8 console provides additional flexibility for producers who need to pull sound bites for podcasts, the web or post-game show highlights.

Maximum control! The Wheatstone LX-24 console in each of the Sports Hub's dual control rooms gives producers total flexibility to switch in local and remote sources, and to route output not only to the station's own air but also to feed team networks and send overflow sports coverage to sister stations. A custom row of buttons on the right side of the console lets any control room take ownership of the Sports Hub air signal.

The first thing visitors see on the second floor of Beasley's two-story building is a pair of windows looking in to the Sports Hub air studio, the result of combining two former production rooms.

5 Key Findings for Commissioning AES67

JULY 2018: Over the summer, we decided to take AES67 out for a spin. We set up a trial run with AES67 devices from Genelec, Ward-Beck, Dante, and Axia into a WheatNet-IP system of 12 mixing consoles, 62 hardware BLADEs (I/O access units), 100 software BLADEs, talent stations, SideBoards, Smart Switch panels, and software including three different vendors’ automation systems. It was all tied together through Cisco and Dell switches. Here is what we learned.

By Andy Calvanese

Wheatstone Vice President/Technology

There’s been a great deal of talk about AES67, but that is as far as it’s gone for most broadcasters – essentially a new standard still sitting on the dealer lot waiting for a test drive.

How easy will it be to commission AES67 in your plant?

We decided to take AES67 out for a spin to find out. Earlier this summer we did a trial run of AES67 through a large WheatNet-IP system staged at the Wheatstone factory in New Bern, North Carolina, during what we call a BLADEFest. (BLADEs are the I/O access units that make up the WheatNet-IP audio network). We do BLADEFests periodically to test our system under real-world conditions, and for this one, we added in a few AES67 devices while we were at it.

We added AES67 devices from Genelec, Ward-Beck, Dante, and Axia into the WheatNet-IP system of 12 mixing consoles, 62 hardware BLADEs (I/O access units), 100 software BLADEs, talent stations, SideBoards, Smart Switch panels, and software including three different vendors’ automation systems. It was all tied together through Cisco and Dell switches.

We ran the system through a series of automated torture tests that included completely rebooting the system and verifying proper operation afterward. We’re happy to say that after more than 160 reboots, not a single connection failure or loss of audio occurred. We also learned a great deal about commissioning AES67 in a plant. Here are a few major findings.

Finding #1. To use AES67 devices, your system must have a PTPv2 clock reference device, preferably synced to GPS for absolute timing reference.

AES67 specifies version 2 of the IEEE-1588 Precision Time Protocol, or PTP, a protocol so precise that under ideal conditions, timing accuracy of better than 1 microsecond can be achieved. While some AES67 devices can provide PTP timing signals which might suffice for a small system, an ordinary crystal oscillator in a PC or I/O device is nowhere near accurate and stable enough to provide an absolute timing reference for a larger system, hence the need for standalone master clock generator.

For even greater timing accuracy you can use PTP compliant switches. These are significantly more expensive and are not needed for normal audio distribution, but are necessary for those applications that require absolute phase accuracy for audio signals distributed across complex networks with multiple switch hops.

Once the PTPv2 clock is running, it’s possible to begin connecting AES67 devices to the network.

Finding #2. Before connecting AES67 devices, map out an IP and stream multicast address plan with all devices on the same IP subnet.

Each AoIP vendor has their own way of allocating addresses; a plan will assure there’s no overlap and that AES67 devices will be on the same IP subnet since multicasting does not normally cross subnet boundaries. Start with the AES67 devices that are least common or least flexible in specifying or changing multicast addresses.

Finding #3. When adding an AES67 device to the network, set the system sample rate at 48kHz unless you know the device sample rate.

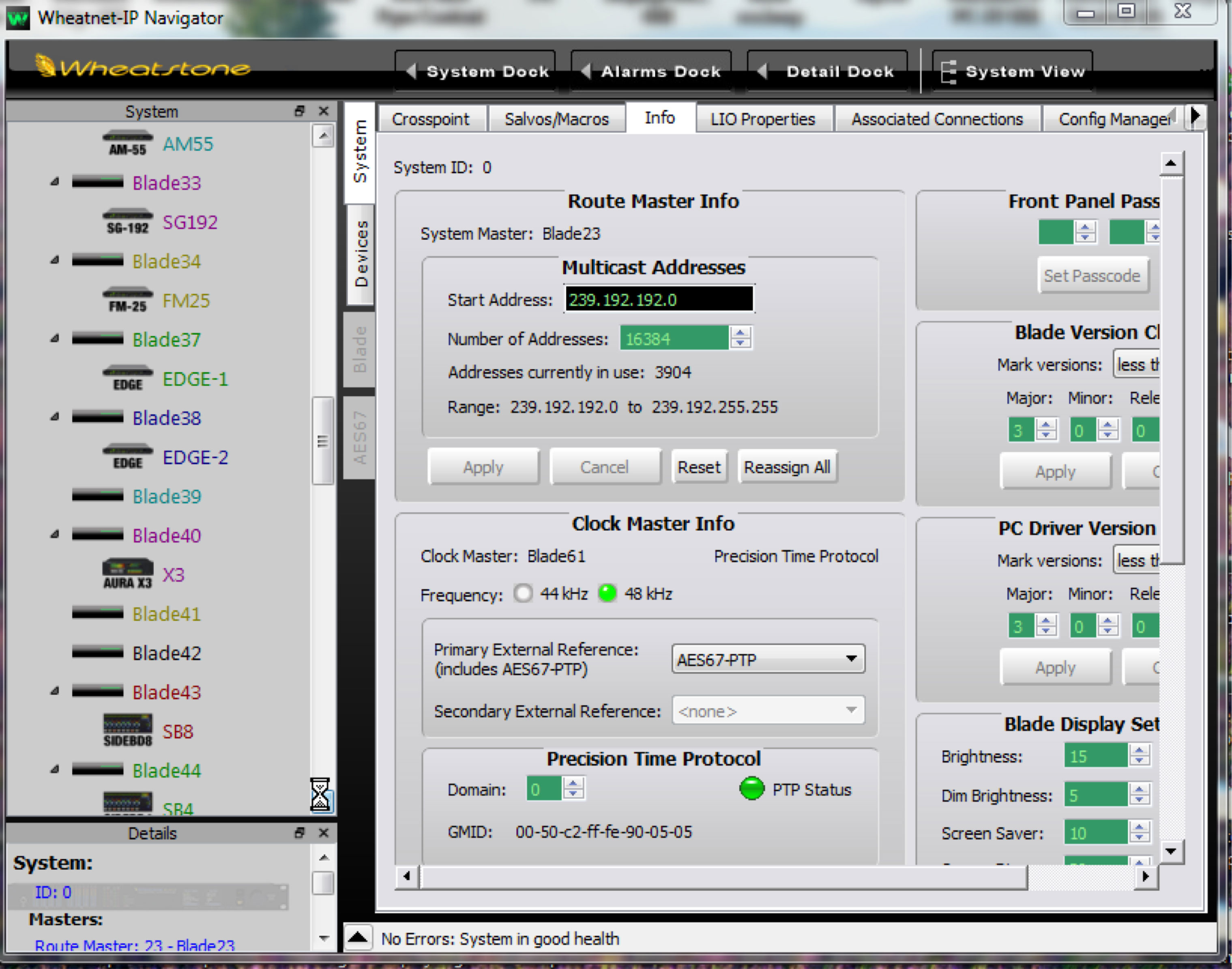

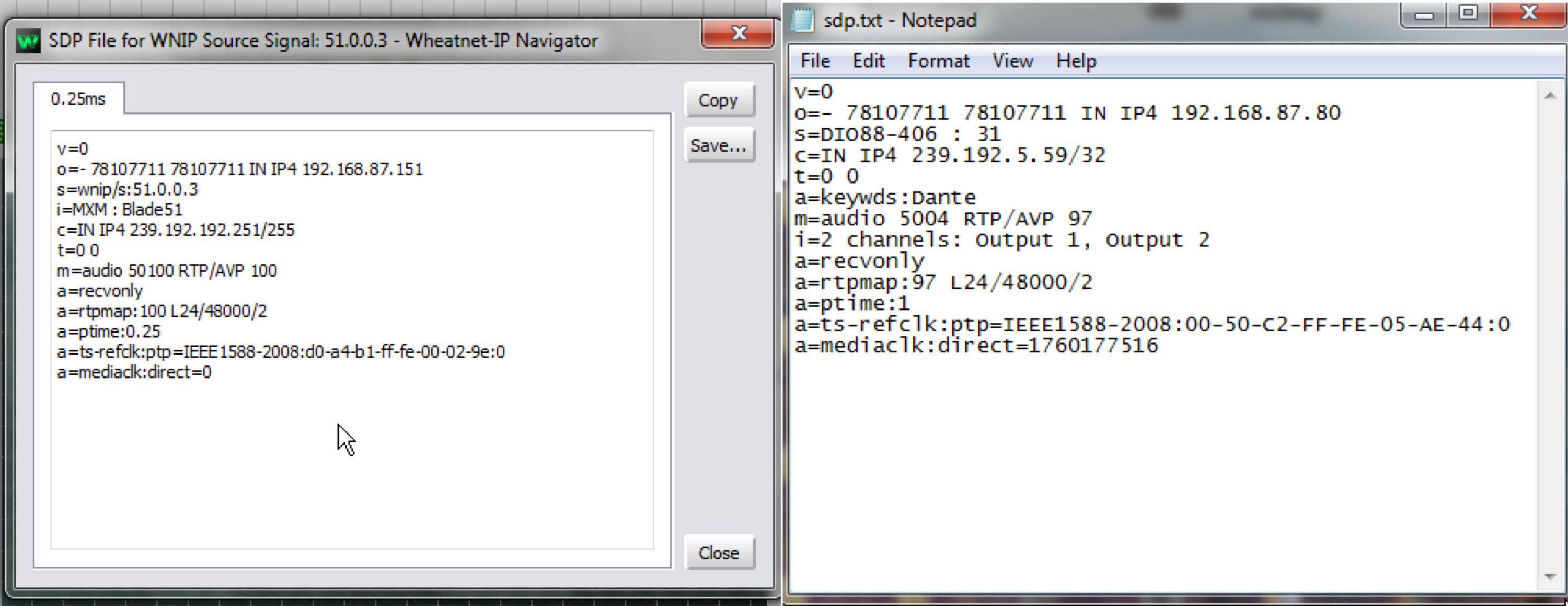

AES67 does not require devices to support 44.1kHz and many do not. You’ll most likely find this setting option and others in the admin software that comes with the network system, such as the WheatNet-IP audio network's Navigator software, an interface screen of which is shown here.

Finding #4. When adding an AES67 device to the network, pay attention to packet timing incompatibilities.

WheatNet-IP uses 1/4 ms packet timing for minimum latency. Most AES67 devices also support 1/4 ms packet timing but some, such as Dante, do not. For those devices that do not use 1/4 ms packet timing, we enabled the AES67 1 ms Support option in WheatNet-IP Navigator, as shown here.

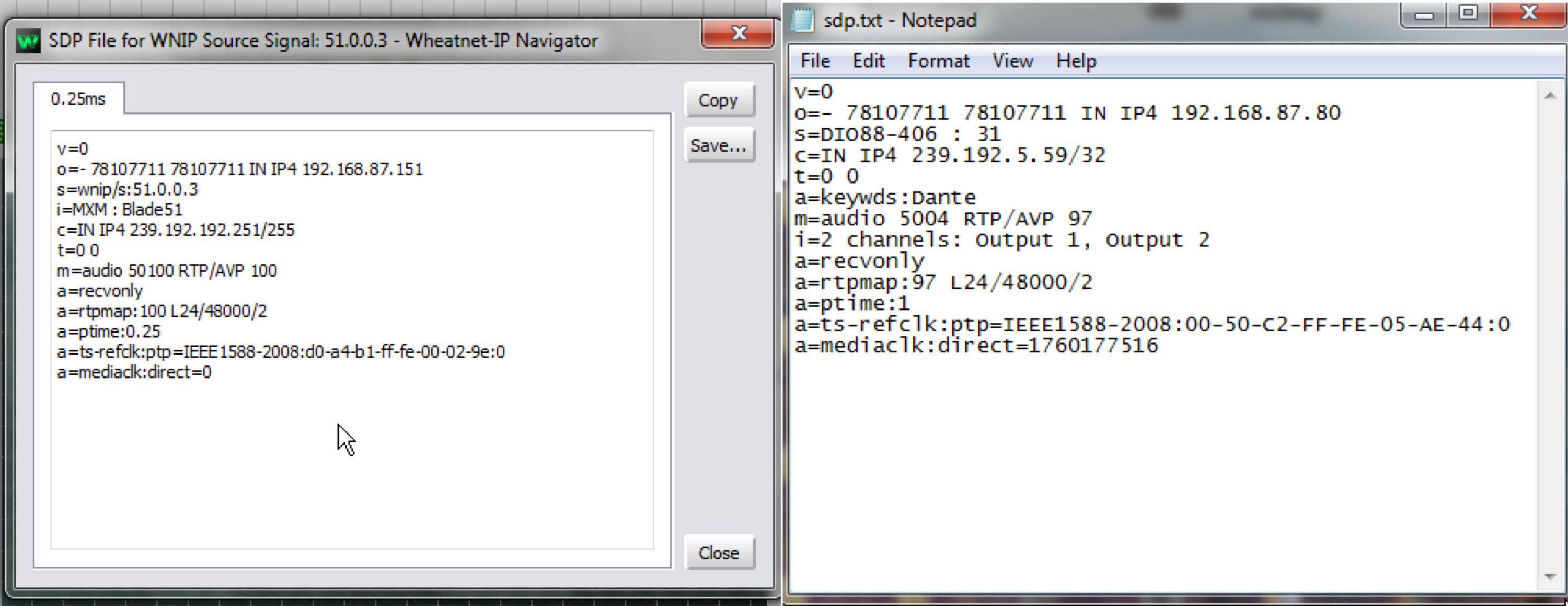

Finding #5. Some AES67 devices do not offer an easy way to manually manage streaming details, although these devices often can read these details in the form of an SDP file.

In our case, we created SDP files by simply right-clicking on the desired source stream’s name in the Navigator crosspoint grid and opening a window that let us create the file.

Below are a few sample SDP files from WheatNet-IP and Dante showing multicast address, packet timing, sample rate and stream formats.

Overall, commissioning AES67 in most broadcast plants should be a nonevent as broadcasters begin adopting the SMPTE 2110 suite of standards.

Overall, commissioning AES67 in most broadcast plants should be a nonevent as broadcasters begin adopting the SMPTE 2110 suite of standards.

Plugfest 2018. We’re Not Talking.

SEPTEMBER 2018: In August, we attended the plugfest in Wuppertal, Germany, which made huge strides in IP interoperability and AES67 compatibility. The results were heard at the IP Showcase during the IBC show in Amsterdam -- one more example of what we as an industry can accomplish together.

Pictured: Danny Teunissen - all things Wheat in The Netherlands and beyond - behind the racks at Plugfest, which we are not talking about...

The first rule of Plugfest 2018 is to not talk about Plugfest 2018 so we won’t tell you that Wheatstone was there with the AES67 goods. Nor will we mention the huge strides we made in IP interoperability, or how much we enjoyed getting together with other industry manufacturers to talk IP in Wuppertal, Germany, last month.

What we can tell you is that the results sounded and looked phenomenal at the IBC show in Amsterdam.

It was all laid out for you at the IP Showcase, where show goers got instruction, case studies, and demonstrations of what we’re talking about – or rather, not talking about. This is the third IP Showcase at IBC and captured the momentum behind the migration to standards-based IP infrastructure for real-time professional media applications.

IP Showcase was hosted by major technical and standards organizations within the broadcast industry: Audio Engineering Society (AES), Alliance for IP Media Solutions (AIMS), Advanced Media Workflow Association (AMWA), European Broadcasting Union (EBU), Society of Motion Picture and Television Engineers® (SMPTE®), and Video Services Forum (VSF).

Our AES67 compatible WheatNet-IP audio network units was there doing their part and demonstrating AES67 compatibility in this overall showcase system based on SMPTE ST 2110 standards. AES67 is a critical part of the move to IP because as the IP audio transport standard specified in SMPTE ST 2110, it can eliminate the practice of HD/SDI audio embedding/de-embedding with video and all the hardware that goes along with HD/SDI workflows. AES67 is an IP audio multicast transport standard that uses the Precision Time Protocol IEEE 1588 as the master clock reference.

A Bad Trip With Diversity Delay

NOVEMBER 2018: Sometimes, we get so caught up in broadcast equipment design and manufacturing that we forget we’re listeners too. Here, Scott Johnson describes the frustration of trying to tune into his favorite show on his morning commute into work, only to have the signal thwarted by HD and FM signals out of alignment.

This morning began like any other. I stepped out the front door, got into my car, and set my radio to the local station that airs a particular newscast I like to listen to while I drive to work.

As I left my neighborhood and headed for the highway, I began to notice something strange. I was having trouble following what the newscaster was saying. It was as if parts of it were missing, but my brain was still a bit foggy. Then I heard a phrase actually repeated. Then there was a skip, then another repeated phrase. Some audio was being repeated and other audio was being dropped. The mystery was solved when I looked down at the display: the radio’s “HD” indicator was coming on and going out at random intervals.

When a station broadcasts the same programming on analog FM as well as their HD1 feed, it’s very easy for the two signals to fall out of alignment due to latency (inherent delay) in the two processing chains. In this case, the analog and HD signals had a time difference between them of nearly two seconds. As my radio blended back and forth between analog and HD, I was hearing two different versions of the audio, one delayed more than the other. The result, with repeated and missing words, was absolutely unlistenable. I changed the station. Your listeners might tune out, too, when faced with the crazy-sounding jitter that bad diversity delay can present them with at the outer fringes of your listening area.

That’s why Wheatstone’s newest processor, the AirAura X4, includes built-in systems for detecting and correcting errors in diversity delay, locking your analog and HD signals together precisely, and readjusting the delay as necessary to maintain that relationship. Alternatively, if you have a Belar or DaySequerra modulation monitor that supports the feature, you can feed its delay correction factor to several of Wheatstone’s on-air audio processors, which will then apply the correction automatically.

You can learn more about Wheatstone’s diversity delay correction technology as well as our partnerships with DaySequerra and Belar on the Wheatstone web site, and in these three informative videos:

Vox on Sports

OCTOBER 2018: Speaking of sports…it seems that our VoxPro digital audio recorder/editor has found its way into the sports arena for live sporting events. VoxPro is mainly used by jocks to manage those fast-paced, live call-in morning shows, but hey, sportscasters do some fast and furious live coverage too and they also need to be able to record and edit simultaneously.

The need to record and edit simultaneously during live shows is not uncommon in broadcasting, but it’s especially vital to sportscasters who cover live sporting events.

That explains why our VoxPro digital recorder/editor has been finding its way into sports venues of late. Commonly used for recording and editing live call-ins for morning radio shows, VoxPro is now being used by the NBA Portland Trail Blazers and other sportscasters for live coverage.

Unique to VoxPro is its controller with scrub wheel plus software editing tools designed specifically for real-time, fast-paced live production. The form and function of VoxPro is dedicated entirely to live coverage so these sportscasters can easily drag and drop sound bites into a Hotkey and add fades and effects as needed, all while editing or recording a separate track in a side window AND sending a mixdown to air!

We’re also beginning to see something else happening in the sports studio. Sound effects and music beds specific to an athlete or a particular play are being prepared in advance and recalled for playback using VoxPro’s Hotkeys.

“I wouldn’t be surprised if we see many other uses for VoxPro by sportscasters as time goes on, especially now that professional games are as much multimedia spectacles as they are contests between two teams,” commented Rick “Doctor Vox” Bidlack, VoxPro systems and design engineer.

Best of Show. Wheat Gets Three.

Every NAB show feels like a finish line. We design, we build, we make changes, we add features, we tweak features. We push ourselves as fast and as hard as we can to bring our individual and collective vision to the industry. We see the first day of the show coming and start counting backward to the cutoff point - the point where we need to pack up what we’ve been working on and take it to the public. But rather than being the finish line, it’s only the next starting line.

We believe we make a difference in the broadcast community. We have ideas - some of which become products, some of which become blueprints for the way forward. We look at the broadcast community every day and evaluate the way it works and the way we work in it, always with a single objective – to improve things. The ways we work; the audio we hear; the ways we interact.

And when we finally get to the show, the excitement of being able to share what we’ve been working on becomes the driving force. We pull out all the stops and make sure we’re presenting it in the best possible way so that you – the broadcast community – can partner with us to implement it all.

While our reward is seeing the difference we make, we’d be lying if we said it didn’t feel great to be recognized by the media in the industry. Next to customer acceptance, nothing’s better for a manufacturer’s self-esteem than receiving a NewBay Best of Show Award. It’s the closest this industry gets to an Oscar and it says that a new product has been evaluated by a panel of engineers and industry experts, and selected based on innovation, feature set, cost efficiency and performance in serving the industry.

So, as we counted down the minutes to the close of NAB 2018, we held our breath, hoping to get at least one Best of Show award.

And guess what? We received three:

Our new ScreenBuilder 2.0 virtual environment creation tool took one from TV Technology.

Our new PR&E EMX AoIP console received one from Radio magazine.

And, yep, even our analog console, the Audioarts Lightning standalone successor to the venerable R-55E, took one from Radio World.

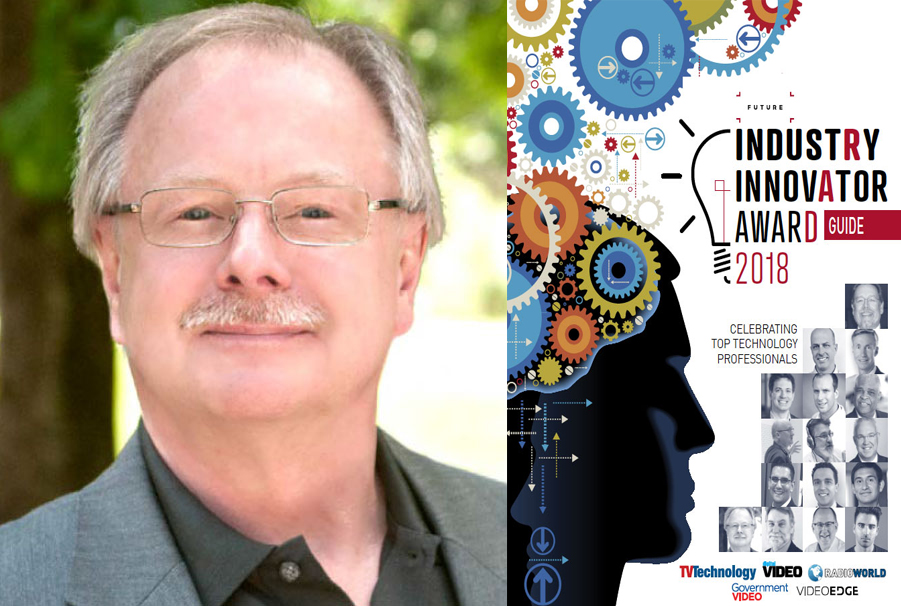

Jeff Keith: Innovator of the Year

Even before Jeff Keith joined Wheatstone in 2007, he earned the nickname "Keithkit" because he was always at the workbench inventing things. Jeff has certainly lived up to that name here at Wheatstone. He's responsible for the multipath mitigation technology you've heard so much about and for an ingenious new approach to clipping that you'll be hearing more about in the coming months.

He's earned his place among the most prominent innovators in our industry, and we're proud he's leading our processing team.

Making Sense of the Virtual Studio

Making Sense of the Virtual Studio

SMART STRATEGIES AND VIRTUAL TOOLS FOR ADAPTING TO CHANGE

Curious about how the modern studio has evolved in an IP world? Virtualization of the studio is WAY more than tossing a control surface on a touch screen. With today's tools, you can virtualize control over almost ANYTHING you want to do with your audio network. This free e-book illustrates what real-world engineers and radio studios are doing. Pretty amazing stuff.

Advancing AOIP for Broadcast

Advancing AOIP for Broadcast

TAKING ADVANTAGE OF EMERGING STANDARDS SUCH AS AES67 VIA AUDIO OVER IP TO GET THE MOST OUT OF YOUR BROADCAST FACILITY

Putting together a new studio? Updating an existing studio? We've put together this e-book with fresh info and some of the articles that we've authored for our website, white papers, and news that dives into some of the cool stuff you can do with a modern AoIP network like Wheatstone's WheatNet-IP.

TV News:

All for One. One for All.

October 2018: There’s nothing quite like a Category 4 hurricane to prove that you can broadcast live from just about anywhere there’s a dry studio and an IP connection. Here’s how Bahakel Communications kept the information flowing for its three Carolina stations in three separate communities during the worst of Hurricane Florence.

On most days in the Carolinas, Bahakel Communications produces newscasts and weather reports from its main newsroom in Charlotte for WCCB-TV, Charlotte; WOLO-TV, Columbia, SC.; and WFXB-TV, Myrtle Beach, SC.

But, on other days when, say, a hurricane pays a visit, live broadcasts can take place just about anywhere there’s a dry studio and an IP connection.

Bahakel Communications has an IP-networked Dimension Three audio console that handles mixing, mic control and IFB for three stations: one in Charlotte, one in Columbia and one in Myrtle Beach, SC. The console is part of the AES67-compatible WheatNet-IP audio network and is located in the main newsroom in Charlotte, which is almost 100 miles from Columbia and more than 150 miles from Myrtle Beach.

All studio cameras, mics, IFB, prompter, weather system, and set monitors in the Columbia newsroom are linked to Charlotte by IP. In Charlotte, it all goes through production and master control, and is then re-encoded with all the sub-channels and sent back to Columbia via IP transport for transmission. The same setup is used for some programming for WFXB-TV in Myrtle Beach. Mid-day weather is presented from the Columbia newsroom, through WCCB-TV production, and fed back via IP to WFXB-TV for air.

At any time, news and weather reports can originate from any of the three locations for all or any of the stations. Should staff need to evacuate one studio location, they can continue to broadcast updates from another studio location. This was the case when Hurricane Matthew required a mass evacuation in Myrtle Beach. As WFXB-TV’s building sat empty and dark, the staff was able to remotely produce live updates for the Myrtle Beach community from the main studio in Charlotte.

For Hurricane Florence, most of the live coverage was done out of the WCCB-TV studio in Charlotte, and our friends at Bahakel Communications tell us that all three stations weathered the storm without incident.

5 Key Findings for Commissioning AES67 (July 2018)

July 2018: Over the summer, we decided to take AES67 out for a spin. We set up a trial run with AES67 devices from Genelec, Ward-Beck, Dante, and Axia into a WheatNet-IP system of 12 mixing consoles, 62 hardware BLADEs (I/O access units), 100 software BLADEs, talent stations, SideBoards, Smart Switch panels, and software including three different vendors’ automation systems. It was all tied together through Cisco and Dell switches. Here is what we learned.

By Andy Calvanese

Wheatstone Vice President/Technology

By now, you’ve heard that AES67 is part of the SMPTE 2110-30 standard and that all the major IP audio vendors offer this audio transport standard as part of their system.

The AES67 format will be useful for streaming audio between the control room and the master control and there’s good reason to believe that it will effectively eliminate the practice of HD/SDI audio embedding/de-embedding with video, and all the hardware that goes along with HD/SDI workflows.

There’s been a great deal of talk about AES67, but that is as far as it’s gone for most broadcasters – essentially a new standard still sitting on the dealer lot waiting for a test drive.

How easy will it be to commission AES67 in your plant?

We decided to take AES67 out for a spin to find out. Earlier this summer we did a trial run of AES67 through a large WheatNet-IP system staged at the Wheatstone factory in New Bern, North Carolina, during what we call a BLADEFest. (BLADEs are the I/O access units that make up the WheatNet-IP audio network). We do BLADEFests periodically to test our system under real-world conditions, and for this one, we added in a few AES67 devices while we were at it.

We added AES67 devices from Genelec, Ward-Beck, Dante, and Axia into the WheatNet-IP system of 12 mixing consoles, 62 hardware BLADEs (I/O access units), 100 software BLADEs, talent stations, SideBoards, Smart Switch panels, and software including three different vendors’ automation systems. It was all tied together through Cisco and Dell switches.

We ran the system through a series of automated torture tests that included completely rebooting the system and verifying proper operation afterward. We’re happy to say that after more than 160 reboots, not a single connection failure or loss of audio occurred. We also learned a great deal about commissioning AES67 in a plant. Here are a few major findings.

Finding #1. To use AES67 devices, your system must have a PTPv2 clock reference device, preferably synced to GPS for absolute timing reference.

AES67 specifies version 2 of the IEEE-1588 Precision Time Protocol, or PTP, a protocol so precise that under ideal conditions, timing accuracy of better than 1 microsecond can be achieved. While some AES67 devices can provide PTP timing signals which might suffice for a small system, an ordinary crystal oscillator in a PC or I/O device is nowhere near accurate and stable enough to provide an absolute timing reference for a larger system, hence the need for standalone master clock generator.

For even greater timing accuracy you can use PTP compliant switches. These are significantly more expensive and are not needed for normal audio distribution, but are necessary for those applications that require absolute phase accuracy for audio signals distributed across complex networks with multiple switch hops.

Once the PTPv2 clock is running, it’s possible to begin connecting AES67 devices to the network.

Finding #2. Before connecting AES67 devices, map out an IP and stream multicast address plan with all devices on the same IP subnet.

Each AoIP vendor has their own way of allocating addresses; a plan will assure there’s no overlap and that AES67 devices will be on the same IP subnet since multicasting does not normally cross subnet boundaries. Start with the AES67 devices that are least common or least flexible in specifying or changing multicast addresses.

Finding #3. When adding an AES67 device to the network, set the system sample rate at 48kHz unless you know the device sample rate.

AES67 does not require devices to support 44.1kHz and many do not. You’ll most likely find this setting option and others in the admin software that comes with the network system, such as the WheatNet-IP audio network's Navigator software, an interface screen of which is shown here.

Finding #4. When adding an AES67 device to the network, pay attention to packet timing incompatibilities.

WheatNet-IP uses 1/4 ms packet timing for minimum latency. Most AES67 devices also support 1/4 ms packet timing but some, such as Dante, do not. For those devices that do not use 1/4 ms packet timing, we enabled the AES67 1 ms Support option in WheatNet-IP Navigator, as shown here.

Finding #5. Some AES67 devices do not offer an easy way to manually manage streaming details, although these devices often can read these details in the form of an SDP file.

In our case, we created SDP files by simply right-clicking on the desired source stream’s name in the Navigator crosspoint grid and opening a window that let us create the file.

Below are a few sample SDP files from WheatNet-IP and Dante showing multicast address, packet timing, sample rate and stream formats.

Overall, commissioning AES67 in most broadcast plants should be a nonevent as broadcasters begin adopting the SMPTE 2110 suite of standards.

Overall, commissioning AES67 in most broadcast plants should be a nonevent as broadcasters begin adopting the SMPTE 2110 suite of standards.

Plugfest 2018. We're Not Talking.

Pictured: Danny Teunissen - all things Wheat in The Netherlands and beyond - behind the racks at Plugfest, which we are not talking about...

September 2018: In August, we attended the plugfest in Wuppertal, Germany, which made huge strides in IP interoperability and AES67 compatibility. The results were heard at the IP Showcase during the IBC show in Amsterdam -- one more example of what we as an industry can accomplish together.

The first rule of Plugfest 2018 is to not talk about Plugfest 2018 so we won’t tell you that Wheatstone was there with the AES67 goods. Nor will we mention the huge strides we made in IP interoperability, or how much we enjoyed getting together with other industry manufacturers to talk IP in Wuppertal, Germany, last month.

What we can tell you is that you’ll get to hear and see the results at the upcoming IBC show.

It’ll all be laid out for you at the IP Showcase in room E106/107. You’ll get instruction, case studies, and demonstrations of what we’re talking about – or rather, not talking about. This is the third IP Showcase at IBC and it promises to capture the momentum behind the migration to standards-based IP infrastructure for real-time professional media applications.

IP Showcase is hosted by major technical and standards organizations within the broadcast industry: Audio Engineering Society (AES), Alliance for IP Media Solutions (AIMS), Advanced Media Workflow Association (AMWA), European Broadcasting Union (EBU), Society of Motion Picture and Television Engineers® (SMPTE®), and Video Services Forum (VSF).

Our AES67 compatible WheatNet-IP audio network units will be there doing their part and demonstrating AES67 compatibility in this overall showcase system based on SMPTE ST 2110 standards. AES67 is a critical part of the move to IP because as the IP audio transport standard specified in SMPTE ST 2110, it can eliminate the practice of HD/SDI audio embedding/de-embedding with video and all the hardware that goes along with HD/SDI workflows. AES67 is an IP audio multicast transport standard that uses the Precision Time Protocol IEEE 1588 as the master clock reference.

Be sure to look for our I/O BLADEs at the IP Showcase and while you’re at IBC, stop by Wheatstone stand 8.C91 and let us know what you think.

Best of Show Awards

April 2018: When we get an award for the products that we sweated over all those months leading up to the NAB Show, it means a great deal to us. For the 2018 NAB Show, we received three awards that represented our key technological achievements. As we start our sprint to this year’s NAB, we’re reminded again that all the products we produce are judged first and foremost by the people who use them.

Every NAB show feels like a finish line. We design, we build, we make changes, we add features, we tweak features. We push ourselves as fast and as hard as we can to bring our individual and collective vision to the industry. We see the first day of the show coming and start counting backward to the cutoff point - the point where we need to pack up what we’ve been working on and take it to the public. But rather than being the finish line, it’s only the next starting line.

We believe we make a difference in the broadcast community. We have ideas - some of which become products, some of which become blueprints for the way forward. We look at the broadcast community every day and evaluate the way it works and the way we work in it, always with a single objective – to improve things. The ways we work; the audio we hear; the ways we interact.

And when we finally get to the show, the excitement of being able to share what we’ve been working on becomes the driving force. We pull out all the stops and make sure we’re presenting it in the best possible way so that you – the broadcast community – can partner with us to implement it all.

While our reward is seeing the difference we make, we’d be lying if we said it didn’t feel great to be recognized by the media in the industry. Next to customer acceptance, nothing’s better for a manufacturer’s self-esteem than receiving a NewBay Best of Show Award. It’s the closest this industry gets to an Oscar and it says that a new product has been evaluated by a panel of engineers and industry experts, and selected based on innovation, feature set, cost efficiency and performance in serving the industry.

So, as we counted down the minutes to the close of NAB 2018, we held our breath, hoping to get at least one Best of Show award.

And guess what? We received three:

Our new ScreenBuilder 2.0 virtual environment creation tool took one from TV Technology.

Our new PR&E EMX AoIP console received one from Radio magazine.

And, yep, even our analog console, the Audioarts Lightning standalone successor to the venerable R-55E, took one from Radio World (see top image in this story).

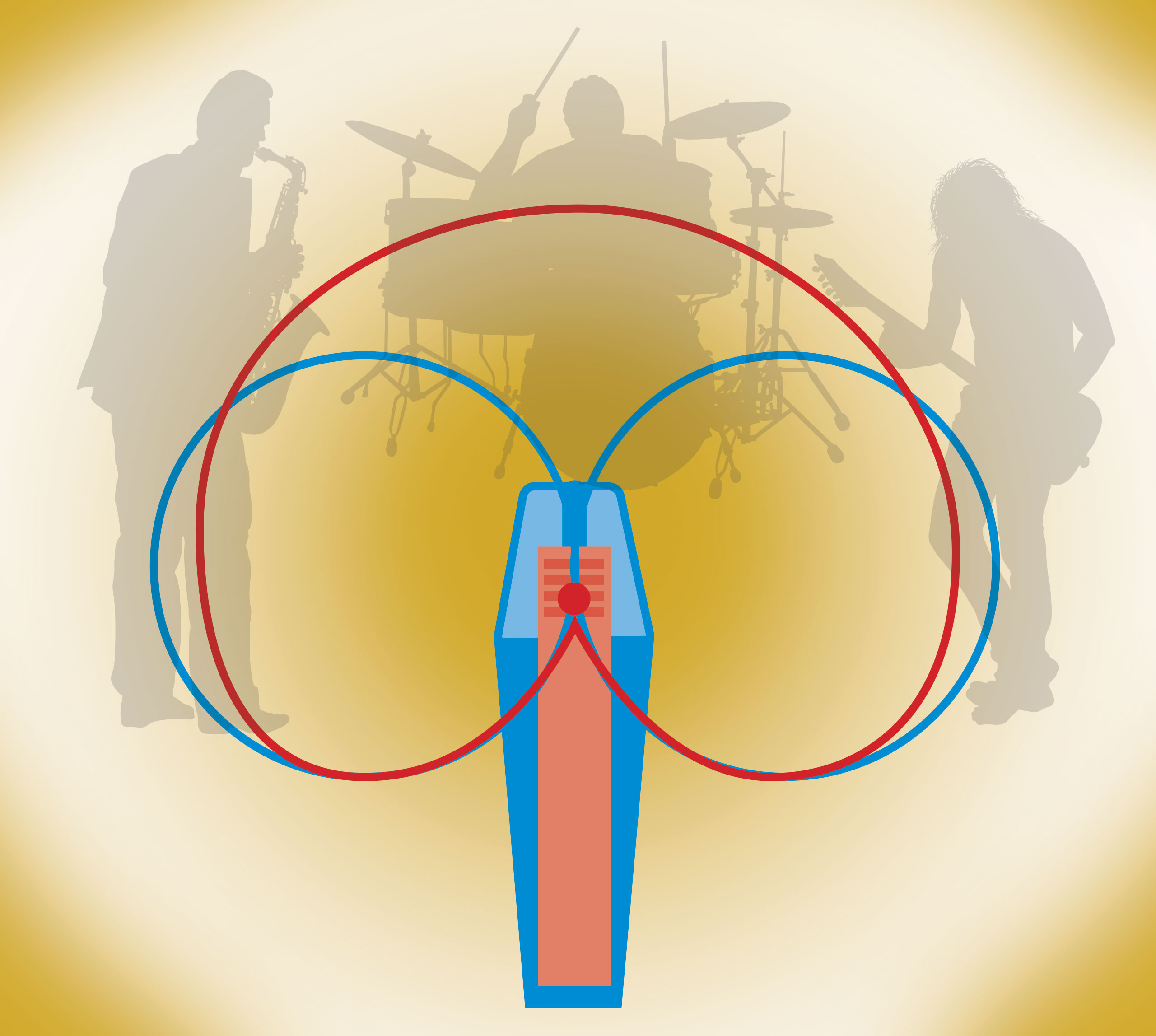

Stereo Miking Technique. (March 2018)

Playing the middle against the sides

By Scott Johnson

Every broadcast engineer finds himself in this situation from time to time. Say your morning news show has brought in a local jazz combo who’ll play into a break. You want a nice, clean, wide stereo image, but you want it to be mono-compatible for all those TV’s in airports, kitchens, and restaurants that have mono speakers.

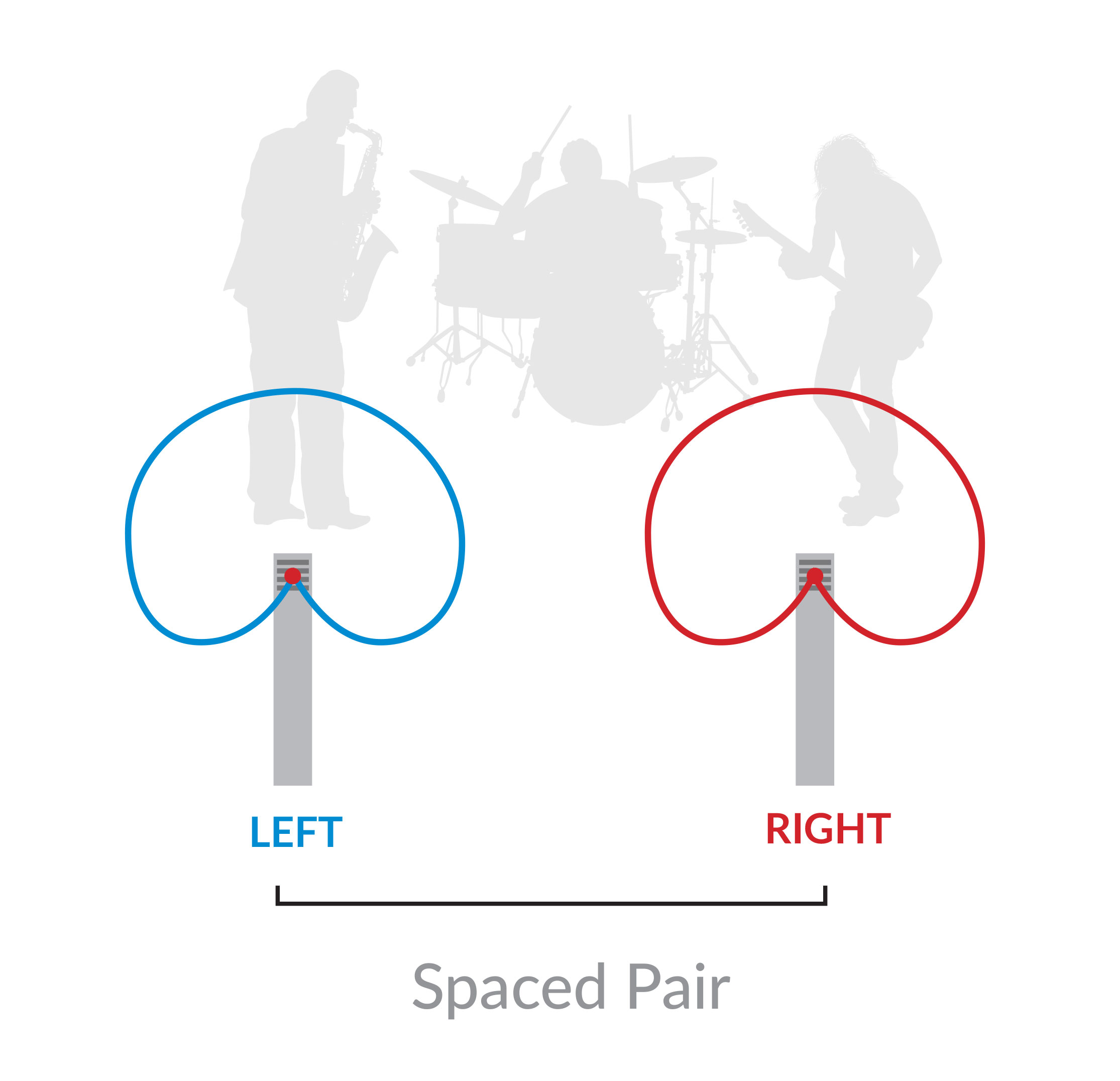

One common technique is the spaced pair, where you place two microphones far apart, just as the early experimenters with stereo sound did. This results in an unnaturally wide stereo listening experience, which we might like. But when it’s collapsed to mono it’s a mess because of phase cancellation. So that one’s out.

One common technique is the spaced pair, where you place two microphones far apart, just as the early experimenters with stereo sound did. This results in an unnaturally wide stereo listening experience, which we might like. But when it’s collapsed to mono it’s a mess because of phase cancellation. So that one’s out.

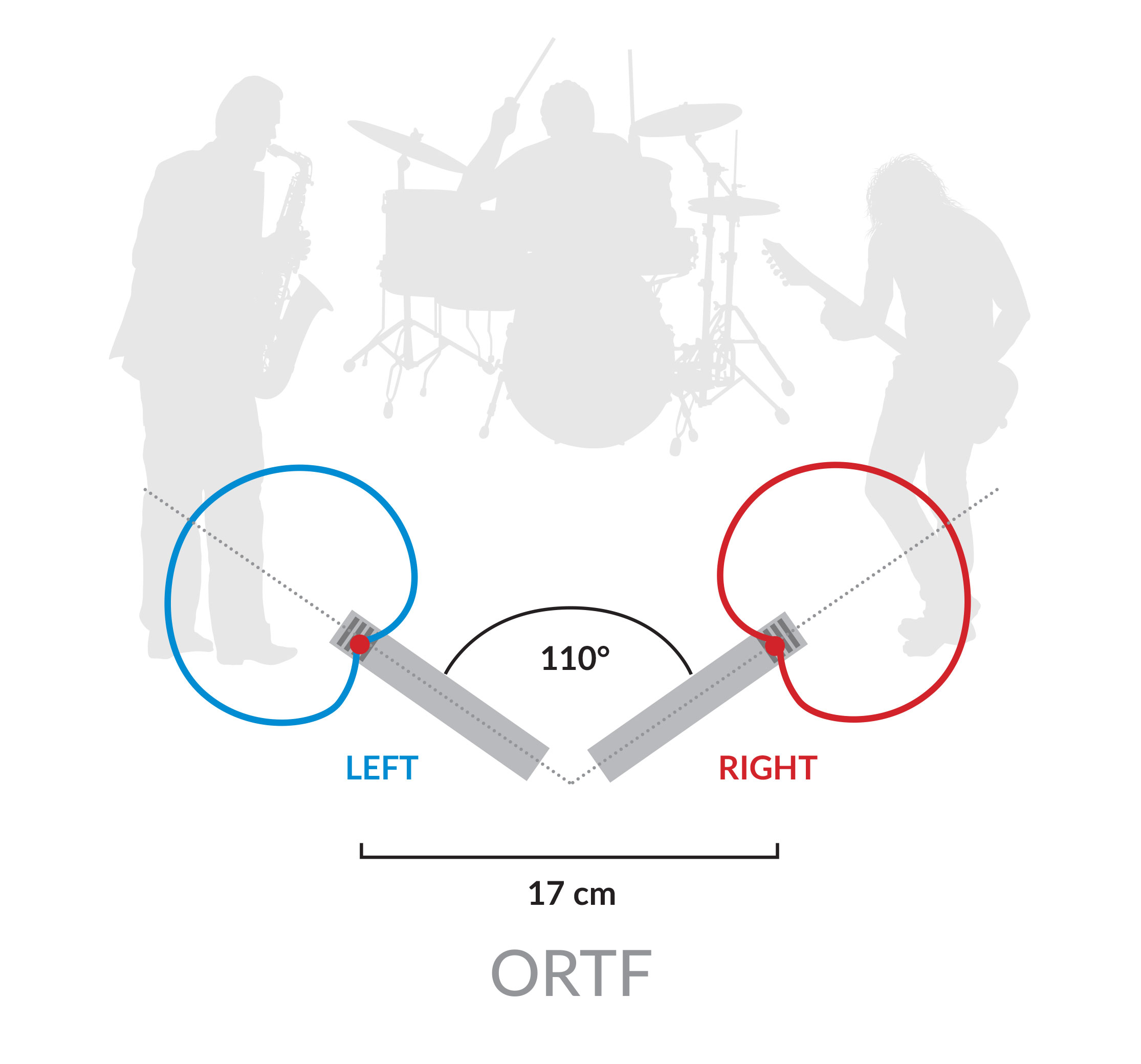

Another method is the near-coincident pair, or ORTF method. (The letters stand for the Office de Radiodiffusion Télévision Française, where the method was invented.) This technique uses two cardioid microphones with their capsules about as far apart as human ears are, and angled at 110 degrees. It produces a very natural sound and is fairly compatible with mono, but the distance between the microphones can cause cancellation at some frequencies.

Another method is the near-coincident pair, or ORTF method. (The letters stand for the Office de Radiodiffusion Télévision Française, where the method was invented.) This technique uses two cardioid microphones with their capsules about as far apart as human ears are, and angled at 110 degrees. It produces a very natural sound and is fairly compatible with mono, but the distance between the microphones can cause cancellation at some frequencies.

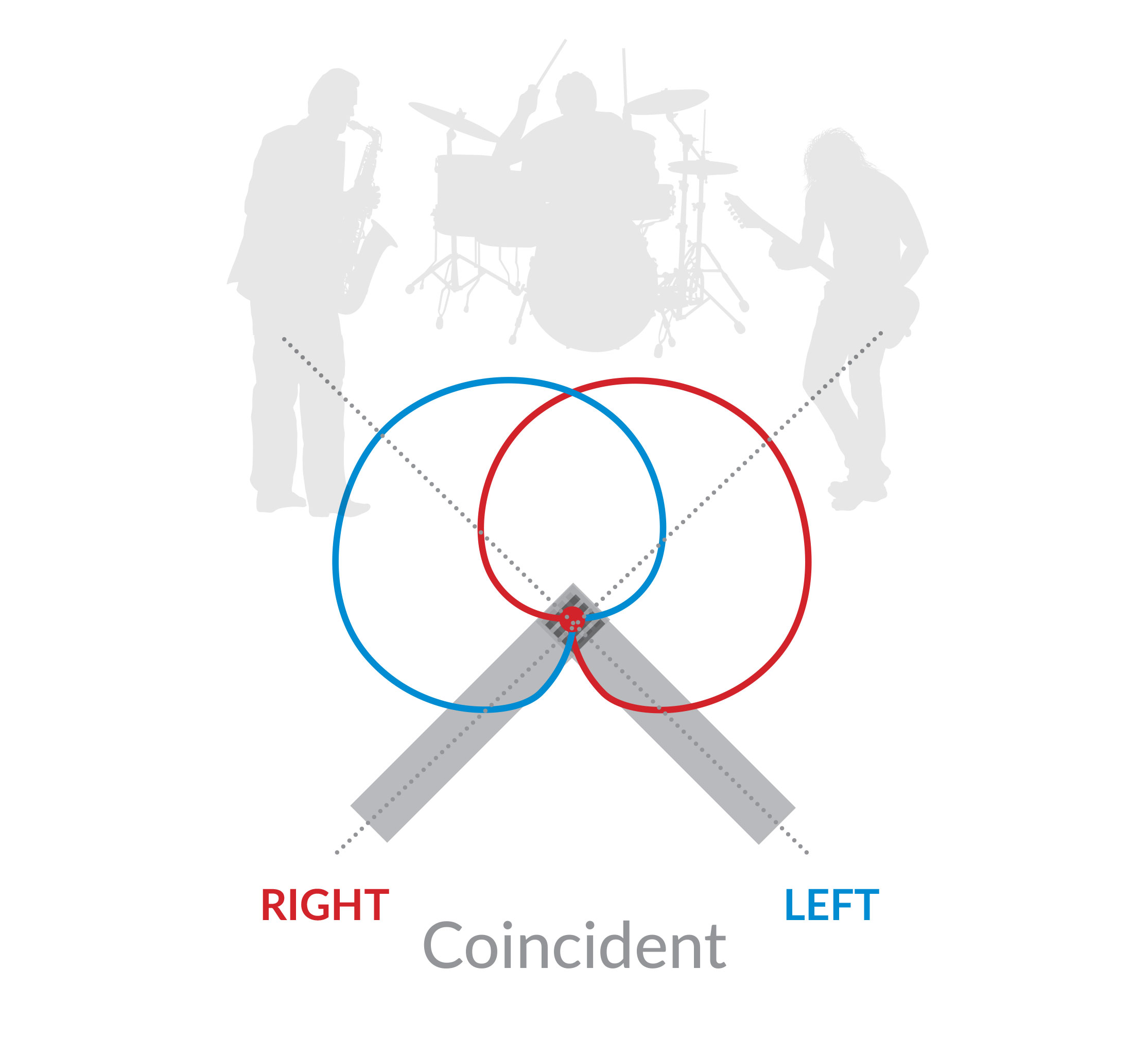

Then there’s the coincident pair. Angling two cardioid mics at 90 degrees with their capsules right on top of each other gives us an expansive pickup pattern, and also prevents virtually all phase cancellation issues since all sounds arrive at both microphones at exactly the same time. The disadvantage here is that the stereo image doesn’t sound as wide or natural. The mic patterns overlap quite a bit, and our ears aren’t perfectly coincident.

Then there’s the coincident pair. Angling two cardioid mics at 90 degrees with their capsules right on top of each other gives us an expansive pickup pattern, and also prevents virtually all phase cancellation issues since all sounds arrive at both microphones at exactly the same time. The disadvantage here is that the stereo image doesn’t sound as wide or natural. The mic patterns overlap quite a bit, and our ears aren’t perfectly coincident.

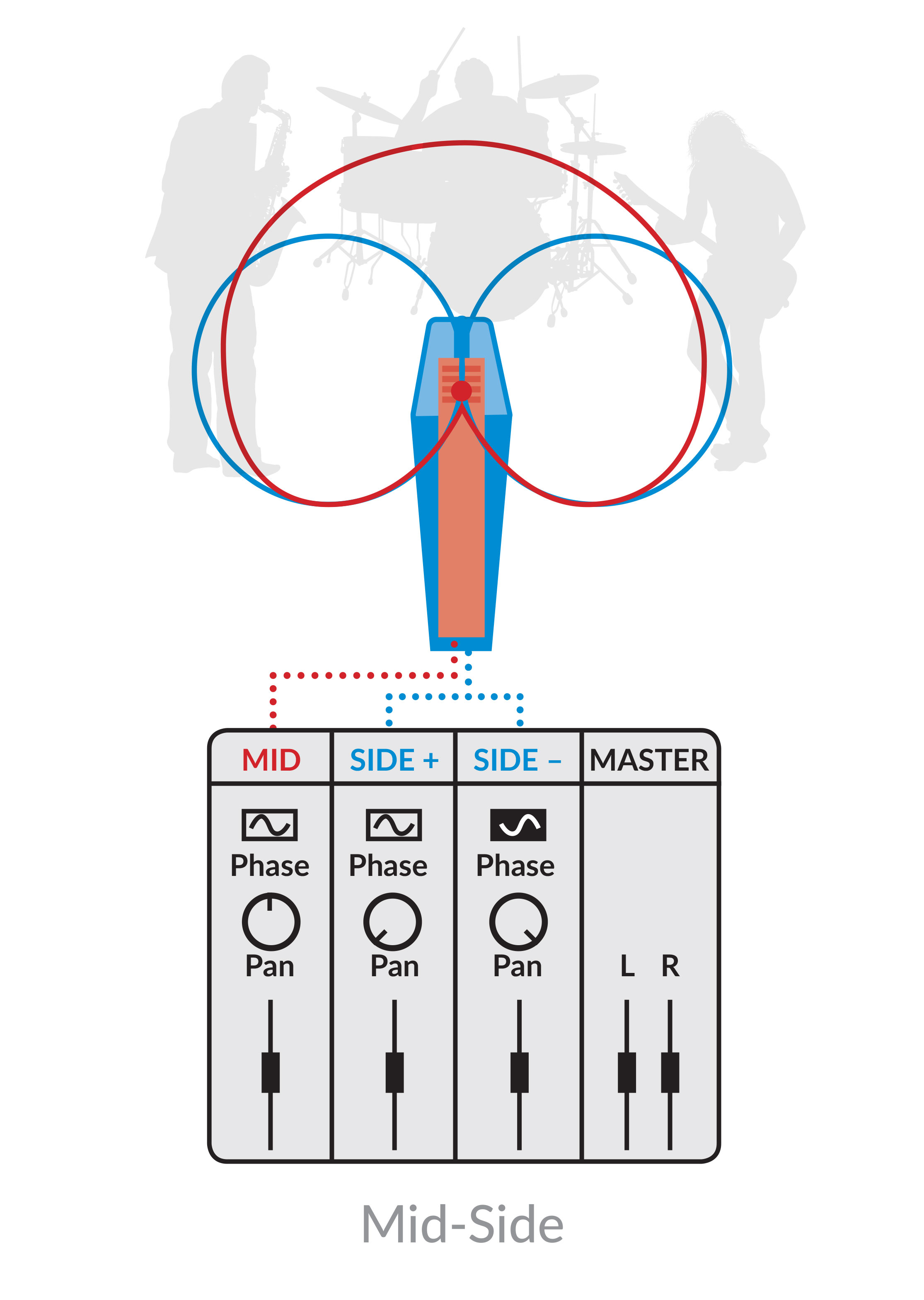

So how do we get the wonderful width and sense of depth of an ORTF pair or even the exaggerated image of a spaced pair, but achieve the same perfect mono coherence as the coincident pair? The best way is with a technique called mid-side (variously abbreviated as M-S, M/S, or just MS) miking. The technique was developed by EMI recording engineer Alan Blumlein, circa 1933, and it’s ideal for broadcast use because while it produces a great stereo image, it’s also totally mono-compatible.

So how do we get the wonderful width and sense of depth of an ORTF pair or even the exaggerated image of a spaced pair, but achieve the same perfect mono coherence as the coincident pair? The best way is with a technique called mid-side (variously abbreviated as M-S, M/S, or just MS) miking. The technique was developed by EMI recording engineer Alan Blumlein, circa 1933, and it’s ideal for broadcast use because while it produces a great stereo image, it’s also totally mono-compatible.

To do this, we’re going to need two microphones. One of them should be a bidirectional microphone. A dual-diaphragm condenser like the AKG C414 is ideal, but any bidirectional microphone will suffice if it’s of reasonable quality.

The other microphone is usually a cardioid. It should be of comparable quality to the bidirectional microphone and is also usually a condenser. A Neumann KM184 is a great choice, but again, microphone selection is not critical to the technique’s success. Only the patterns matter.

The bidirectional mic is placed on a stand with its capsule facing left and right. Generally, the “front” or “positive” side of the mic faces left and we will assume that here.

The second mic is placed facing the source. For reasons of phase coherence, it should be as coincident with the other mic as possible; ideally, its capsule should rest right above the bidirectional’s capsule.

So now we have cables from two microphones headed back to the console, and that’s where we do the interesting part: matrixing these middle and sides signals to a left/right pair. We’ll need three faders to do this.

So now we have cables from two microphones headed back to the console, and that’s where we do the interesting part: matrixing these middle and sides signals to a left/right pair. We’ll need three faders to do this.

On fader 1, we’ll assign the middle (cardioid) microphone. We’ll set it to a nominal level and pan it center on our stereo bus.

On fader 2, we’ll assign the bidirectional (sides) microphone. We’ll pan it to the left on our stereo bus.

On fader 3, we’ll assign the sides microphone again. (On an analog console, we can do this with a Y cable, or by way of the patch bay.) On this fader, we REVERSE the phase (polarity) of the incoming signal and pan it to the right.

Now all we have to do is set the trims on faders 2 and 3 to a nominal level, ensure they’re both set to exactly the same level, and bring up all three faders. You’ll be capturing a very wide, rich stereo field thanks to the combined patterns of the three microphones.

Here’s the best part. Try moving the level of the middle mic. As you pull it down, you’ll sense that the stereo image widens. If you push it up higher, the stereo image will narrow.

How does it work? For purposes of discussion, let’s call the middle mic M and the sides mike S.

The left channel of the stereo bus is receiving M + S, meaning that the sounds arriving at the left side of the sides microphone are being added to the middle mic signal.

The right channel is seeing M – S, meaning that sounds arriving at the right (back) side of the sides mic are being added to the middle mic signal. We flipped the polarity on this fader so that the sounds arriving at the back (right side) of the bidirectional mic, which are naturally of opposite polarity from the front, will again have the same polarity as the middle mic and add properly.

Signals arriving from dead center will enter both the front and back sides of the bidirectional mic at the same time, producing opposite signals that cancel, so those sounds are picked up only by the middle mic and are fed to both sides of the stereo bus.

But more importantly, because the two side mic faders are precisely level-matched and opposite in polarity, their contributions to the mix are exact opposites, and if the stereo bus is summed to mono, the sides signals will cancel out, leaving a perfectly clean mono signal from the middle mic. No mono compatibility problems can arise.

There are a couple of variations on the technique. You can try using an omnidirectional microphone for the middle channel, which makes the entire array essentially a stereo omni microphone. This can accentuate the pickup of room tone and reverberation if your room has good acoustics. You can also use a second bidirectional microphone for the middle channel with similar results, extending the pickup pattern.

The technique isn’t just for music, either. M-S miking a live shot, for example, or a speech before a live audience, has a tendency to put the viewer right in the middle of the crowd, improving overall fidelity of the experience. It’s even a good way of capturing crowd or environmental sounds that will later be mixed with a voice-over, dialogue, or an interview as stereo nat sound.

Mid-Side miking can save the engineer a great deal of time and aggravation, capturing a clean, clear, dimensional stereo image that’s ideal for television broadcast. It’s a technique every audio engineer should have tucked away in his bag of tricks.

Scott Johnson is a systems engineer and webmaster for Wheatstone. He has plenty of mic techniques up his sleeve as a lifelong audio engineer. When he’s not experimenting with Wheatstone mixers and mic processors, he can be found at the local community theater mixing sound for the latest production.

Sportscast Like A Pro

Collegiate sportscasting, we’ve been told, is a contact sport. It’s all about being on the field and in the moment. No one knows how to do this better than pros like Mike Janes, the Vice President of Engineering and Technology for the NBA Portland Trail Blazers, who has been a student of the game for more than 20 years.

He says that you don’t have to be in the big leagues to produce compelling sportscasts. Even if sporting events are a small part of your larger broadcast mix, you can still cover college football, basketball or baseball games like a pro with these few simple tips.

1. Add to the picture with multiple microphones. “If you have only one camera for, say, a small college football game, it makes sense that you’ll be shooting from the stand. But you have a lot of area down below on the field to cover, so use microphones to add dimension to that picture,” advises Janes, who recommends shotgun mics for this purpose. His crew places microphones on each side of the basketball court, both underneath the nets and on the ground pointing away from the basket to catch effects. They also place a mic at the free throw line and an XY pair on center court. “Audio is one of the more underappreciated aspects of what we do,” says Janes. (Full disclosure: Portland Trail Blazers uses our WheatNet-IP audio network with E-6 IP mixing console at its production studio in Portland).

2. Keep everyone in the loop. Things can change in an instant. Everyone on your team needs to be in the loop, and that includes the technical director at the home studio as well as the announcers on the ballfield, and everyone in between. The Trail Blazers uses a complex intercom system that loops in more than 30 production crew members at one time, including the graphics designer for generating logos and other graphics as the game rolls. Your intercom doesn’t have to be as complex, but it does need to be a reliable backchannel of communication that includes all crew members. Mixing consoles made for broadcast have talkback features that can be useful for this purpose. Even better: IP consoles, the IP audio network of which can serve as the backbone for a simple, easy-to-set-up IFB system and other purposes.

3. Be able to call the shots. It’s one thing to report from the steps of the Capitol Building, but it’s something entirely different to cover the play-by-play of a game. In broadcast sports, the key is knowing where the ball is going next – and that requires a good understanding of the game. “Most of our guys are very tuned into the sports they’re covering,” comments Janes.

4. Have backups of backups. When things go wrong in sportscasting, they tend to go wrong in a hurry. You’ll want spares, and spares of spares. That includes routing equipment and paths, and codecs, mics, mixers, headsets, and power cords. “I learned the hard way; have backups of backups,” says Janes.

Got feedback or questions? Click my name below to send us an e-mail. You can also use the links at the top or bottom of the page to follow us on popular social networking sites and the tabs will take you to our most often visited pages.